BENDING MACHINES

Press BrakesPFO

OVERVIEW

The PFO series synchronised press brakes from Fratelli Farina are available in a wide range of tonnages and beam lengths with multi-axis configurations.

Throughout our 40-year history we have manufactured press brakes for almost every kind of plate bending application across all spectrums of industry working with sheetmetal.

Our press brakes are derived with three main principles : machine durability operational reliability high bending precision.

The machine frames are generously dimensioned to minimise mechanical deflections.

In addition, Fratelli Farina has specific and very effective solutions as regards to final press brake accuracy and repeatibility in the form of : deflection frame control active compensation thickness measurement.

Personalisation of the machines to special customer demands is traditionally one of the strengths of Farinas engineering department.

FEATURES

Specially engineered frame design for maximum structural integrity and minimum bend deflection.

Large throat daylight stroke dimensions as standard ( also configurable by customer request).

Ram with double guides to warrant linear movement.

Synchronised downstroke bending with multi-axis backgauge options.

Machine control by user-friendly cnc units.

Cnc crowning of the lower beam.

Hydraulic compensation of the lower beam for enhanced accuracy.

PLATINUM PACKAGE for a total solution to bend precisely without operator intervention.

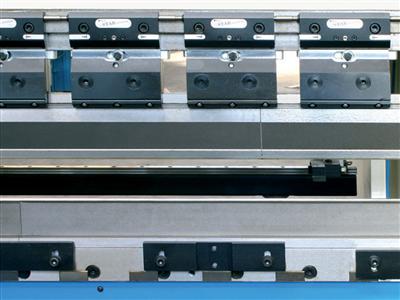

Tooling system by adjustable intermediaries in the top and self-centering holder in the bottom.

Quick release top tool clamping.

Pneumatic top and lower tool clamping.

Wila-system hydraulic top and lower tool clamping with Wila tooling.

Tooling for hemming.

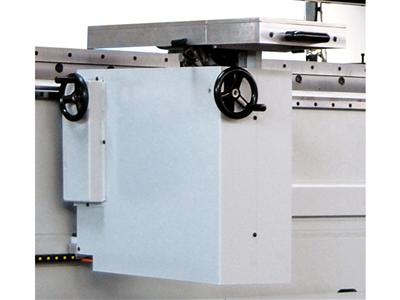

Sliding and fully adjustable front arms on linear guides as standard.

Automatic and motorised sheet followers by cnc.

Start-stop technology for power saving.

Online servicing over internet VPN connection.

Hydraulic, electrical, mechanical components from globally-known brands with high standards.

Pre-arrangement for future tandem operation.

Pre-arrangement for future robotics integration.

Laser guarding DSP AP or LAZER SAFE.

Deflection frame control |

|

|

Bending of sheets of various length

without changing the parameters Bending of sheets that have been notched or drilled without changing the parameters Possibility to test bending operations on pieces of reduced sizes, and then carry out the same bending operation on the real pieces without changing the parameters No delay in working time This system is not visible and does not create any obstruction to the bending operations |

Active compensation system |

|

|

Constant angle on the whole length Total control of the compensation system Completely automatic Constant angle laterally and in the center No decrease in speed No visible and obstructive measuring equipment |

Thickness measurement system |

|

|

Increased precision Totally automated Decrease in waste of material Check of material No delay in bending process No visible and obstructive measuring equipment |

MACHINE CONTROLS

All Farina press brakes are controlled by powerful cnc units recognised for being user-friendly with easy programming and having application flexibility for machine operators.

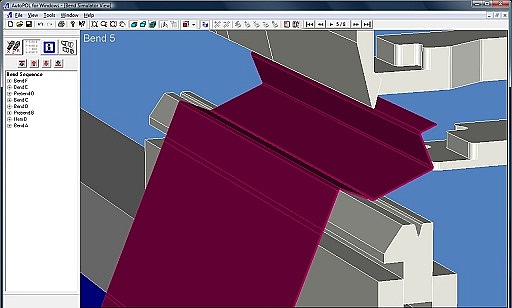

Delem DA 69T 3D multi-axis graphical control

Delem DA 66T 2D multi-axis graphical control

Software for offline programming

Autopol INFOLAB BEND cad/cam bending simulation software

All standard and optional backgauges on the Farina press brakes are exclusively made in Italy for Fratelli Farina.

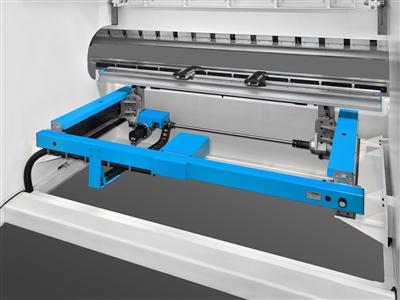

X-R two-axis standard backgauge

X-R two-axis standard backgauge X-R-Z1-Z2 four-axis backgauge

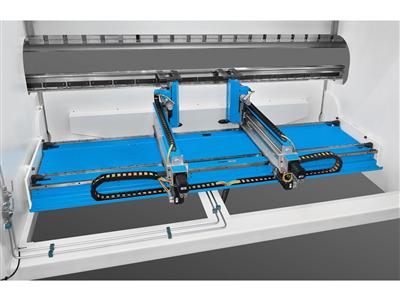

X-R-Z1-Z2 four-axis backgauge X-R-Z1-Z2-X3-X4 six-axis backgauge with pneumatic finger

X-R-Z1-Z2-X3-X4 six-axis backgauge with pneumatic finger X1-R1-Z1 / X2-R2-Z2 six-axis modular backgauge with independent fingers

X1-R1-Z1 / X2-R2-Z2 six-axis modular backgauge with independent fingersOther available backgauge options :

X1-X2-R three-axis backgauge

X-R-Z1-Z2-X3 five-axis backgauge

X1-X2-R-Z1-Z2 five-axis backgauge

Machine Technologies for Plate Bending and Cutting

Machine Technologies for Plate Bending and Cutting